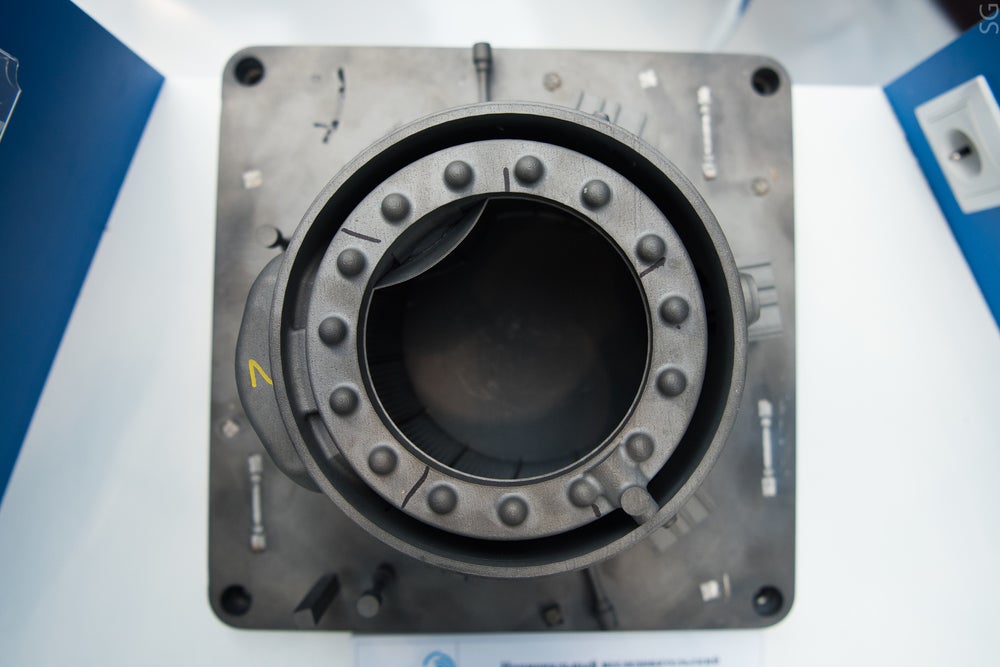

In what is believed to be a world first, engineers have 3D printed the entire engine body of a VK-2500 helicopter, reducing the time to manufacture it to just 14 days.

The helicopter’s internal engine body was 3D printed from titanium alloy powder using an additive manufacturing technique known as selective laser melting, which uses a high-density laser to melt and form metallic powders into pre-programmed shapes.

The technique eliminated the need for the usual machine techniques, significantly reducing the time of manufacture. This means that if the production process was used commercially, it could make the cost of production – and so the retail price of the resulting helicopter – significantly lower.

The feat was achieved by engineers from Russia’s National University of Science and Technology (NUST MISIS) and St Petersburg Marine Technical University (SMTU), with the resulting engine body currently being displayed at the MAKS International Aviation and Space Salon.

3D printed helicopter engine body highlights potential of technique for aviation

The project showcases the potential of selective laser melting for the aviation industry. While 3D printing is increasingly being used within the field, selective laser melting remains an emerging technology, particularly in Russia.

The 3D printed helicopter engine body follows the creation of a full-size prototype of a domestic PD-14 aircraft engine in August at NUST MISIS.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataThe university is engaging in ongoing research in this space to fulfil a government decree to develop large-sized units for the aviation industry.

“The presented functional unit is really unique,” said Evgeny Zemlyakov, project executor, deputy director for scientific and design activities, from the Institute of Laser and Welding Technologies at SMTU.

“We can definitely say that this is the first part of such complexity and such size obtained in Russia using the technology of selective laser melting from domestic powder materials.”

Read more: GKN Powder Metallurgy acquires Forecast 3D in 3D printing push