Automobile manufacturers face a quandary. Demand for feature-rich, environmentally friendly vehicles is booming. But stretched supply chains and tariff uncertainty is raising unprecedented logistical and financial hurdles.

The rush towards CASE – connected, autonomous, shared and electric – has widened the field of competitors and production partners in the auto world. The industry’s vibrancy is clear. The connected vehicles market was worth $38.5 billion in 2024, and is projected to climb to $52.9 billion by 2030. It highlights where the value is moving and the rising bar towards which mainstream manufacturers must now strive.

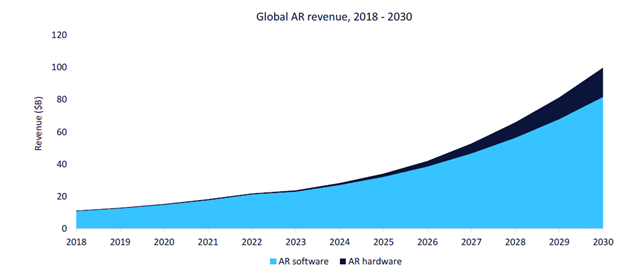

Underpinning this growth is a range of powerful production technologies overhauling manufacturing processes. GlobalData projects global augmented reality revenue will reach $100 billion in market value by 2030, up from $22 billion in 2022.

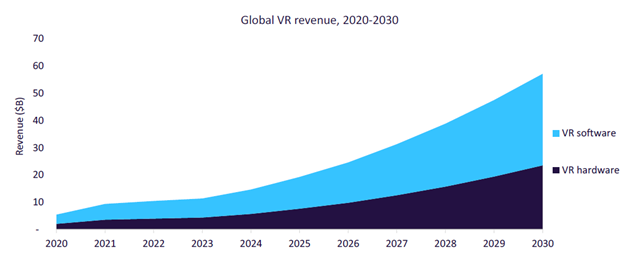

The virtual reality market is set to generate $57 billion over the same period, as training, data visualization and design review use-cases harden. These key points underpin the digital twin; digital representations of real-world products, and automotive companies understand their importance. With extended reality offering a new approach to design and digital twins establishing a single source of truth across operations, Immersive Engineering is bridging the gaps between virtual prototypes, the shopfloor and vehicles on the road.

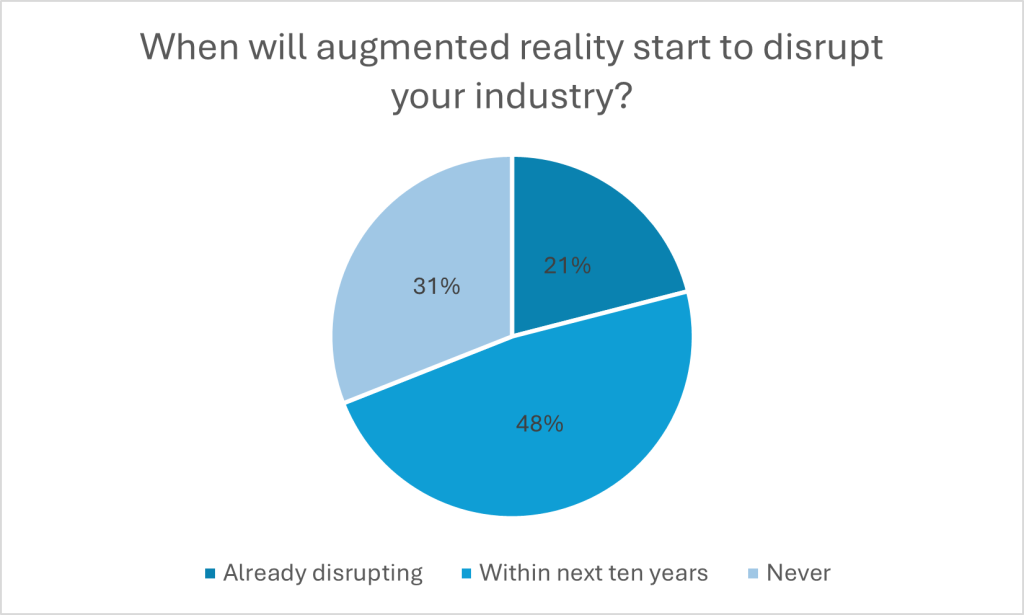

According to a recent GlobalData survey of top-level business decision makers on disruptive technologies, the trajectory is clear: nearly 70% of respondents believe augmented reality will begin making a tangible impression on business-as-usual over the coming decade. The productivity boost it will offer is going to be indispensable in answering the challenging supply chain and economic questions faced by the auto industry.

Yet adoption varies by technology and by firm. Those experiencing the greatest payoff are pursuing disciplined deployment into specific, high-value use-cases.

Immersive Engineering: Use Cases in Auto

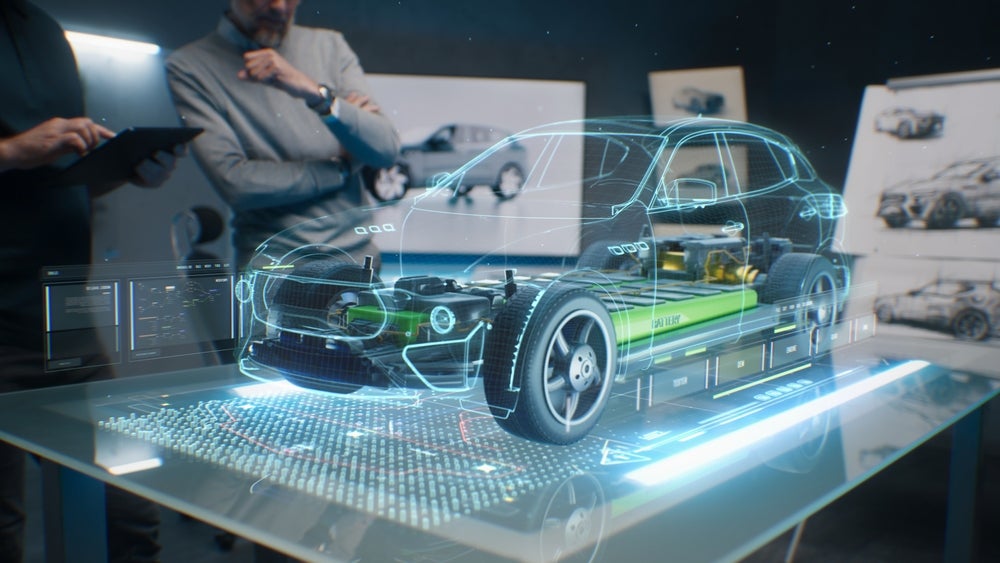

Immersive Engineering revolutionizes the way in which automotive design teams can collaborate. Design reviews remain the heartbeat of development; many are still mediated through static slides manually arranged, time consuming meetings and traditional on-screen reviews. It’s an approach that limits a team’s ability to get a true sense of scale for a new product.

Immersive reviews let engineers, designers and manufacturing teams interrogate full-scale models together. In doing so, they can explore important constraints around things like visibility, packaging, design optimization and assembly constraints in minutes rather than weeks.

Efficiency in the manufacturing process itself can be turbocharged by Immersive Engineering. Digital twins bridge design decisions and factory reality through simulation, diagnostics and what-if analysis. Layout changes, work instructions and quality checks can be stress-tested before pledging capital. And, once that capital is committed, having a single, digitised source of truth can keep processes on track even when dispersed teams and suppliers need to be negotiated. In short, the right data in an intuitive environment compresses time to consensus.

Briggs Automotive Company (BAC), a specialist OEM, has implemented Sony’s SRH-S1alongside Siemens’ Immersive Engineering software tools to improve 3D CAD modelling, visualize changes to components in real time and align teams across Europe. Designers at BAC replicate the digital twin of their fully road legal supercar, the Mono, directly inside Siemens Immersive. The result? Greater flexibility for customer specific customization, cutting re-work required on physical parts.

It highlights how the benefits of Immersive Engineering can be brought to the shopfloor, introducing feedback forward into the design phase, keeping everyone working on the same models and shortening iteration loops.

Integrate Immersive Engineering Today

Immersive Engineering is changing the game. Rather than exporting models to a standalone visualization tool and re-prepping data after every change, Immersive Engineering all runs on the same Designcenter NX session. The software’s one-click, integrated workflow contrasts with traditional non-associative pipelines that add delays, introduce potential errors and force rework whenever the design moves on.

Immersive Explorer supports instant design reviews, with markup, sectioning, snapshots and live updates flowing from NX into the immersive session; teams can join from anywhere, and colleagues without a headset can navigate the scene in desktop mode. Immersive Collaborator creates shared virtual meeting rooms so engineers, production planners and suppliers can examine the same vehicle, annotate issues and take decisions as a group.

Collaboration at enterprise scale is enabled over the cloud with Designcenter X NX, hosting meeting services and leveraging value-based licensing capabilities. Stakeholders across the company or supply chain step into one virtual environment, removing siloes and empowering teams to conduct quick, targeted reviews at the right time.

And the innovation doesn’t stop at software. Siemens have partnered with Sony to create the SRH-S1; an XR head-mounted display with high-fidelity visuals, balanced ergonomics and controllers designed for intuitive product design. It is a device engineers and designers can wear throughout a review without fatigue, flip up when needed and integrate seamlessly into a normal engineering day.

What does this deliver? Siemens cites productivity gains of up to 30% compared to traditional processes. And tighter collaboration and fewer physical prototypes delivers sustainability as well as cost benefits. In the automotive lifecycle, the benefits are clear. For concept and styling, full-scale immersive viewing exposes proportion, surfacing and visibility issues early. In package engineering, teams can test important features like service access without having to build costly, bulky prototypes. In manufacturing engineering, line planners and suppliers explore station ergonomics and tooling clearances against the live product model.

When quality or service teams spot issues on physical builds, changes can be made to the digital twin of the product instantly, including, annotating the dataand closing the design loop. Overheads around exporting and reconciling versions disappears – accelerating decision-making.

The direction of travel is set. Sustained growth in XR looks set to continue, with solid enterprise use for collaboration and training penetrating the industrial world… Automotive firms that want quicker cycles, fewer physical prototypes and a tighter connection between design and production can get ahead of the curve by integrating Siemens Immersive Engineering. Fill in your details on this page to learn more.