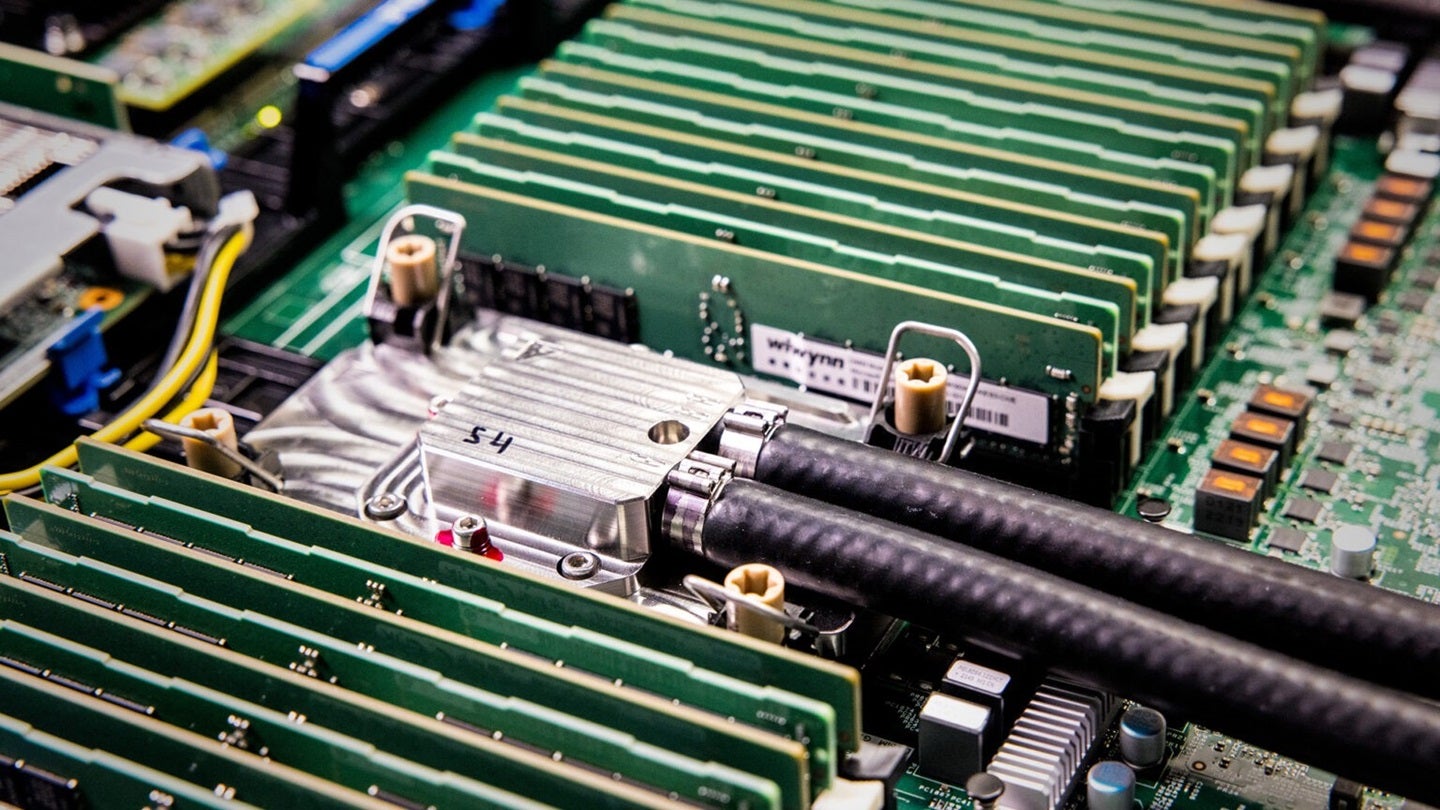

Microsoft has reported the successful testing of a new cooling system for data centres that outperforms current technologies.

According to a report by Catherine Bolgar on Microsoft’s official website, this innovation, called in-chip microfluidic cooling, can remove heat up to three times more efficiently than the commonly used cold plates.

Access deeper industry intelligence

Experience unmatched clarity with a single platform that combines unique data, AI, and human expertise.

The new system addresses the issue of heat generated by AI chips, which has been increasing with each new generation of technology.

The cooling system uses microfluidics, a method that directs liquid coolant directly into the silicon chip. This is achieved by etching minuscule channels on the back of the chip, allowing for effective heat removal.

Bolgar wrote that the research team used AI to identify unique heat signatures within a chip to direct the coolant more precisely. Microsoft claims this approach could enhance efficiency and sustainability for future AI chip designs.

During lab-scale tests simulating a Teams meeting, microfluidics reduced the maximum temperature rise inside a GPU by 65% and improved power usage effectiveness.

US Tariffs are shifting - will you react or anticipate?

Don’t let policy changes catch you off guard. Stay proactive with real-time data and expert analysis.

By GlobalDataSashi Majety, senior technical programme manager for cloud operations and innovation at Microsoft, highlighted the necessity of moving beyond traditional cold plate technology within five years to keep pace with evolving AI chip designs.

According to Microsoft, creating effective microfluidic systems presents significant engineering challenges. The dimensions of these cooling channels are comparable to human hair, requiring precise design and manufacturing processes.

Microsoft corporate vice president and cloud operations and innovation chief technical officer Judy Priest said: “Microfluidics would allow for more power-dense designs that will enable more features that customers care about and give better performance in a smaller amount of space.

“But we needed to prove the technology and the design worked, and then the very next thing I wanted to do was test reliability.”

Microsoft worked with Swiss startup Corintis to use AI in developing a bio-inspired channel design, resembling natural structures like leaf veins.

Over the past year, Microsoft produced four iterations of the design as part of its prototyping efforts. The process involved creating a leak-proof package for the chips, finding optimal coolant formulas, testing various etching methods, and establishing a manufacturing process.

The company plans to further explore integrating microfluidic cooling into future generations of its chips and collaborate with partners for broader implementation across its data centres.

Recently, Microsoft unveiled plans to invest $4bn over the next three years to build a second AI data centre in Mount Pleasant, Wisconsin. This brings the company’s total investment in the state to more than $7bn.