3D printers incorporated into cooking devices could help mitigate disease transmission and enable the calibration of food nutrition content.

In a report entitled The Future of Software-Controlled Cooking, published on 21st March, 2023, mechanical engineers at New York’s Columbia University outline a successful prototype demonstration for the 3D printing of a slice of cake.

The report explains how the Covid-19 crisis highlighted the need for less human intervention in food preparation to mitigate the risk of disease transmission. In addition, 3D food printing enables users to precisely calibrate the nutrient content of their food which could significantly improve on today’s mass-market, nutritionally deficient, processed food.

However, the use of 3D printers for food preparation instead of conventional cooking appliances such as oven and microwaves will require a significant cultural shift.

Though many industry sectors are exploring the potential benefits of 3D printing with materials such as plastic, metal, rubber and concrete, food technology is becoming a viable field for the application of 3D printing technology.

While prototype exploration, such as the Colombia University study are valuable, the industry needs to progress towards mass manufacturing, says GlobalData analyst Carolina Pinto.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalData“3D printing has always been closely associated with prototyping and short production runs. Today, the industry wants to expand into mass manufacturing. To facilitate this transition, 3D printing companies must guarantee product standardisation, particularly in industries such as automotive, aerospace, and healthcare,” says Pinto.

The industry’s growth towards mass manufacturing, over the next few years, will require integrate existing hardware and software technologies and does not necessarily require further innovation, according to Pinto.

3D technology has been in development since the 1980s. It has made a mark on the manufacturing world, but there is much more to be done, says Pinto. “The industry no longer needs to prove that 3D printing works but must now establish its place in the manufacturing mix,” she adds.

GlobalData thematic research predicts that the value of the 3D printing industry will reach $70.8bn by 2030, having grown at a compound annual growth rate of 18% between 2021 and 2030. The software segment of the industry will deliver the fastest growth as companies prioritise adopting workflow automation tools, according to the analyst.

Venture capital funding in 3D printing technology has increased steadily over the last decade, reflecting the GlobalData’s growth prediction.

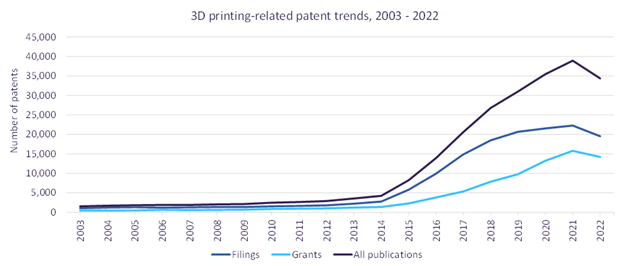

According to GlobalData, patent filings for 3D printing and related technologies exponentially increased between 2013 and 2021, with more than 10 times as many patents published in 2021 as in 2013. A decline in registered patents in 2022 was likely related to the technology moving toward maturity, says Pinto.