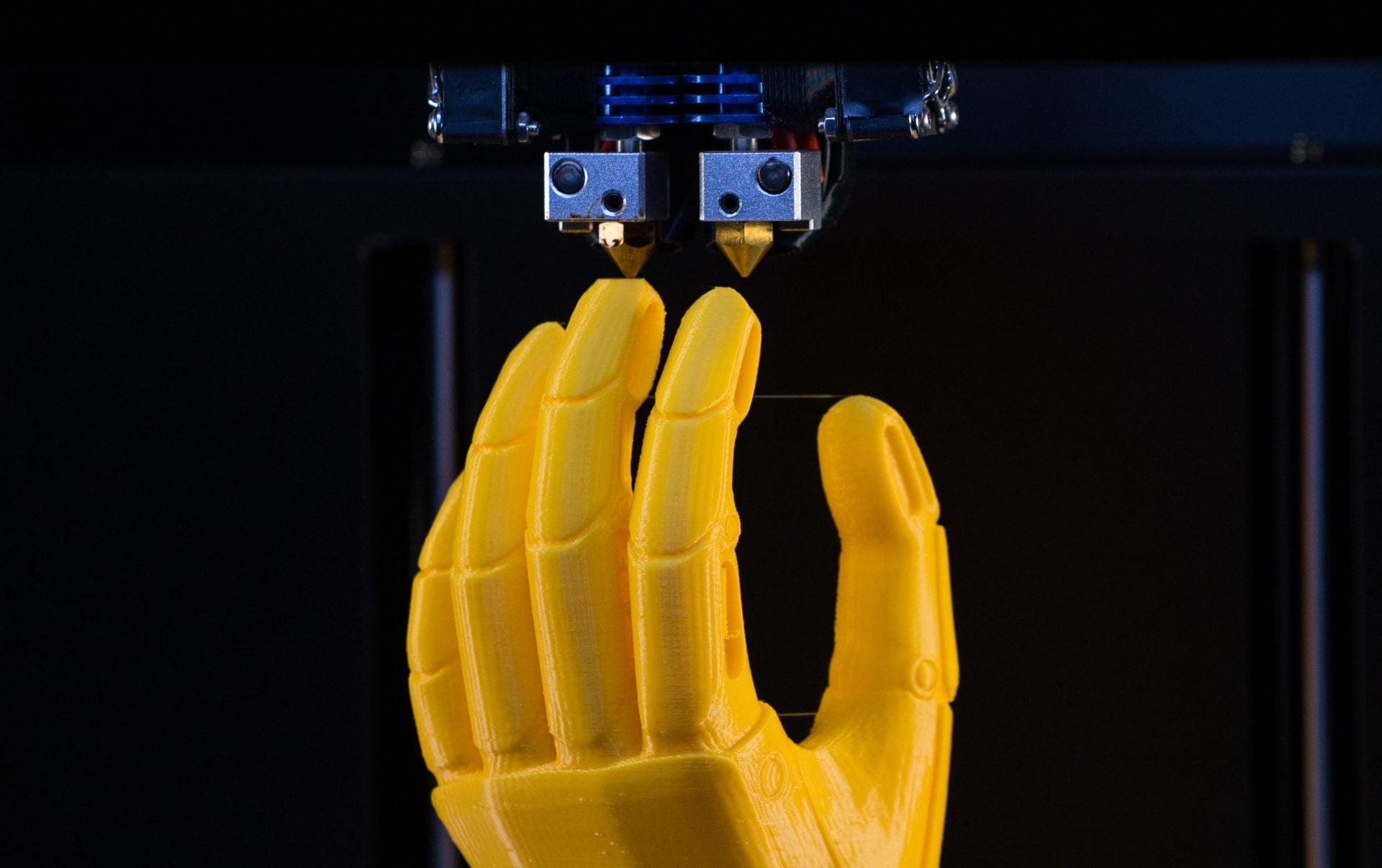

First emerging as a concept back in the 1980, additive manufacturing in which 3D objects are produced from a model on a computer by building up layers of material, is by no means a new technology.

Attracting much attention by many who claimed it would one day revolutionise the manufacturing industry, companies have been slow to reap the benefits of 3D printing technology.

However, one company who remained notably absent from the 3D printing market was HP. Perhaps one of the best-known manufacturers of paper printers, HP refrained from entering the market when the hype surrounding the technology was at its highest.

After parting ways with the other half of the company, Hewlett Packard Enterprise, in 2015, HP Inc. is now betting on cutting-edge technologies and security to propel the company into the future.

Part of this plan to develop “solutions that benefit society as a whole”, HP is now investing in what is believes is a key pillar of industry 4.0: 3D printing.

At HP’s annual Innovator Summit, Verdict spoke to Shane Wall, HP’s chief technology officer and the director of HP labs, about why he thinks the company has the technology to disrupt digital manufacturing for good.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataLaunching its first additive manufacturing platforms in 2016, Wall explains that the company made the decision to wait until it could have a sizable impact on the field:

“We always said it was an interesting area but we did not want to go into it before we felt we had a true disruption whether it could be ten times faster, it could be a tenth of the cost or it could be significantly better quality. And once we invented Multi-jet Fusion we had it. And that’s when we started pushing on the pedal. You can’t schedule an invention.”

“We have a chance to radically change 3D printing”

Back in 2016 the company launched the Jet Fusion 3200 and 4200, and in the three years since then has moved into full-colour printing, printers capable of producing different textures, and last year announced printers capable of printing stainless steel, coming to market in 2020 for $400,000. Just yesterday, the company announced the launch of its 5200 series, boasting “new levels of manufacturing predictability, efficiency and repeatability”.

Now the company is focusing on high-volume manufacturing, with three goals of making 3D printing faster, cheaper and better quality.

It is hedging its bets on its patented technology, known as Multi Jet Fusion. With many companies looking to invest in this lucrative area, HP Wall explains that technological advances have enabled HP to address some of the shortcomings in existing 3D printing technology:

“With multi-jet fusion, which we invented five to seven years ago, we have a chance to radically change 3D printing and more importantly manufacturing. Multi-jet fusion is technology we invented that actually prints digitally, which is very unique compared to any other technology.

“We print at a volumetric pixel, and that’s a 20 micron point in space that we can individually print all of those microns. And we do it in parallel all one layer at a time whereas every other technology is analogue. You’re putting down a layer.”

Enabling digital manufacturing

As demand for 3D printed parts continues to grow, HP is working closely with new and existing digital manufacturing partners around the world as they expand their HP Multi Jet Fusion fleets.

The company is now working with a number of partners, from startups such as Glaze Prosthetics, a company creating highly personalised 3D printed prosthetics using a HP Multi Jet Fusion printer to a partnership with Jaguar Land Rover to improve its in-house 3D printing capabilities.

Although 3D printing has had a definite impact on the manufacturing industry, with the proportion of companies who consider themselves to be a 3D printing-first companies increasing from 15% to 22% in 2018 according to Forbes, the technology has had its drawbacks, with many 3D printers prohibitively expensive, or limited by slow print times or the limited number of materials they can produce.

What started off has plastics now encompasses a range of materials, highlighting the substantial effort HP has put in to truly disrupting the area :

“We can print polymers and metals. We can change the colour. We can change the elasticity, we can change the conductivity so we can print electronics into the parts. All of those are the key parts that enable real digital manufacturing. And that’s a 12 trillion dollar opportunity.”

As well as its versatility, HP’s Jet Fusion 3D Printing solution boast printing times far faster than rivals:

“It’s way times faster than current technology. For example, can take a full-size part, and you’re talking minutes or up to one to two hours versus something that could have taken hundreds of hours to complete. So the speed is incredible. And that’s because it goes in parallel, we print an entire layer at a time versus one bit at a time.”

“Hugely positive for the Earth”

However, aside from creating a new business area for the company, Wall believes that the widespread adoption of 3D printing has the potential to disrupt the manufacturing industry as a whole.

It is estimated that around a third of the world energy production is consumed by manufacturing, with around 5% taken up by shipping goods to the location where they are needed. Wall predicts that switching to digital manufacturing could save around 25% of that total energy used, largely through on-demand manufacturing:

“If you can do this on demand, and print where you need it, when you need it you eliminate warehouses, you eliminate distribution centres, you eliminate balance sheet items, it becomes hugely positive for the Earth as well as somebody themselves.

He also explains how the technology can enable greater tractability, helping manufacturers and customers tackle the issue of counterfeit goods and unethical supply chains:

“Today if you manufacture a simple plastic part you don’t know where it got made or how it got made. But the great thing about digital 3D printing is you can now put specific water marks in the print itself that you can’t see but you can detect easily. That means that every part you print can have a unique ID.”

“One of the key pillars for HP that will build a multi-billion dollar business”

He believes that moving forward, 3D printing will play a substantial part in HP’s business:

“Our goal is to build a very substantial business. We think this is one of the key pillars for HP that will build a multi-billion dollar business moving forward. We think about it as how can we change a community? How can we change how we create goods, how can we eliminate waste? If you have something that can do both, how can you not do it?”

However, in the future Wall envisions that 3D printing could form the basis for the ultimate circular economy, with 3D printers effectively able to print themselves:

“When you combine 3D printing with AI and machine learning capabilities things get really interesting. Half of the parts in our 3D printer today were printed by the printer itself. So the printer’s manufacturing itself. Now we’ve added in metals we’ll soon do the same thing with the metal parts of the printer. Imagine a world where you build a prototype, and then the prototype builds itself. And then it starts printing its own parts. Now what I can do because of digital watermarking, every part I print on that printer can be tracked uniquely. So when it lands in another printer, I can now track the performance of those parts in the entire fleet. So when I figure out that there’s an error in those parts using machine learning, I can figure out that there’s a problem, I can figure out the changes I can make, and each of the printers can reprint a part to go back in themselves.”